题图1

题图4

题图2

题图3

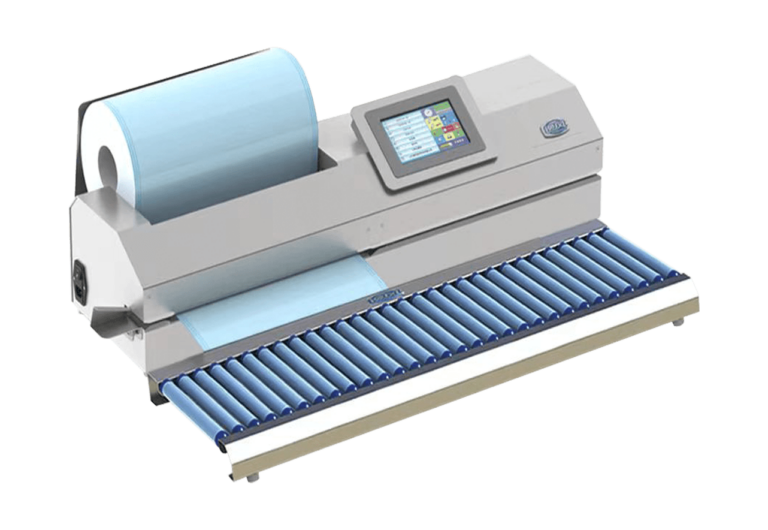

Low Temperature Hydrogen Peroxide Plasma Sterilization DLZ60

The DLZ-60 features a 70-liter capacity chamber, compact dimensions, and convenient installation options. Combined with its extremely low power requirements, this makes it an ideal plug-and-play solution for small medical centers, as well as a supplementary device for large medical facilities.

模式一.png)